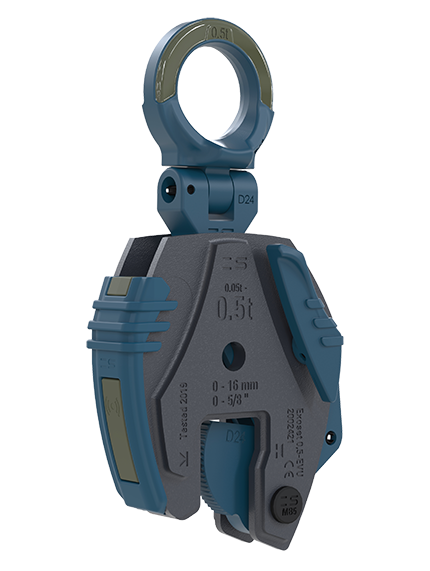

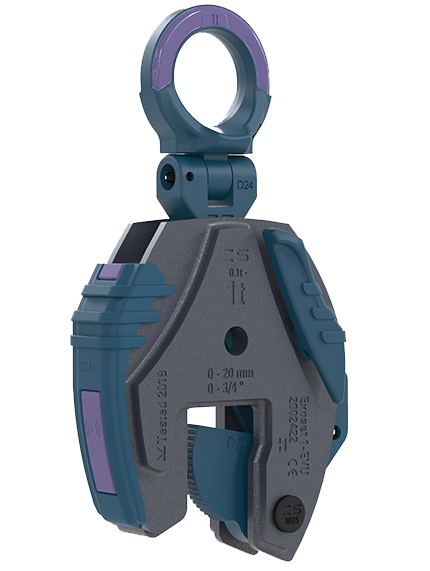

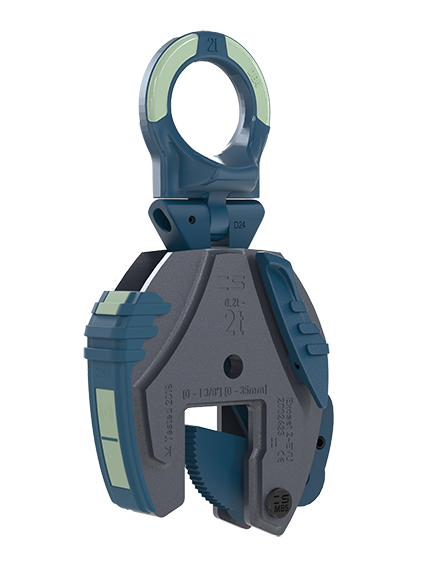

The Spanset Exoset Vertical Lifting Clamp is the only lifting clamp in the world certified by DNV‑GL (Type Approval ST‑0378), offering unparalleled safety assurance. Engineered for vertical lifting and turning of steel plates and structures, it features a self-locking cam mechanism, wear and maximum load indicators, and a hinged hoisting eye for multi-directional use. Rugged yet lightweight, this clamp delivers Swiss-engineered reliability for demanding industrial, construction, and fabrication environments.

- 5-year warranty

- Made in Europe

- Only Lifting clamps in the world with DNV certification

- Available for Regular Steel, Stainless Steel & Hardox

- Meets ASME B30.20

- Meets ASME BTH-1 Design Category C

- Meets ASME BTH-1 Service class 4

Documentation

- Available in capacities 0.5t-6t. Higher WLL and different jaw openings are available upon request

- Individually Proof Tested to 2x the Working Load Limit with certification

- Breaking Load Limit of 6x Working Load Limit (WLL)

- Minimum WLL needed is 10% of maximum WLL (5% available on special order)

- Temperature range -40°C/+100°C

- ASME BTH-1 Design category C (Design Factor of 6:1) & Service Class 4 (Over 2,000,000 load cycles)

- Regular Clamp For use with materials with a surface hardness up to 364 HV, tensile strength 1200 N/mm2.

- EVU-S for vertical lifting, transporting and turning for stainless steel plates. With a maximum hardness of 364 HV, tensile strength 1200 N/mm2.

- EVU-H for vertical lifting, transporting and turning of all steel plates with a maximum hardness of 473 HV, tensile strength 1550N/mm2. (for example, Hardox 400 and 500).

- Maintenance kits in stock for all models

| |||||||||||||

| Model | WLL(t) | Jaw aperture mm [in] | Dimensions mm [in] | Product weight [lb] | |||||||||

| A | B | C | D | E | F | G | H | I | J | ||||

| EVU-0.5 | 0,5 | 0-16 [0-0.63] | 39 [1.54] | 226 [8.91] | 134 [5.29] | 40 [1.59] | 41 [1.63] | 22 [0.88] | 114 [4.49] | 13 [0.53] | 20 [0.80] | 28 [1.12] | 1.9 [4.19] |

| EVU-1 | 1 | 0-20 [0-0.75] | 39 [1.54] | 237 [9.35] | 145 [5.73] | 52 [2.06] | 44 [1.74] | 28 [1.12] | 127 [5.00] | 13 [0.53] | 20 [0.80] | 28 [1.12] | 2.1 [5.29] |

| EVU-2 | 2 | 0-35 [0-1.38] | 68 [2.68] | 375 [14.78] | 209 [8.24] | 76 [2.99] | 61 [2.43] | 48 [1.90] | 192 [7.58] | 18 [0.71] | 32 [1.27] | 44 [1.74] | 7.6 [18.3] |

| EVU-3 | 3 | 0-40 [0-1.56] | 73 [2.89] | 446 [17.56] | 262 [10.34] | 101 [4.01] | 71 [2.80] | 55 [2.17] | 299 [9.30] | 22 [0.90] | 42 [1.65] | 58 [2.28] | 14.8 [32.6] |

| EVU-5 | 5 | 0-40 [0-1.56] | 73 [2.89] | 446 [17.56] | 262 [10.34] | 101 [4.01] | 71 [2.80] | 55 [2.17] | 299 [9.30] | 22 [0.90] | 42 [1.65] | 62 [2.44] | 16.0 [35.3] |

| EVU-6 | 6 | 0-50 [0-2.00 | 80 [3.15] | 549 [21.64] | 327 [12.89] | 131 [5.19] | 97 [3.84] | 59 [2.32] | 284 [11.18] | 37 [1.46] | 42 [1.65] | 62 [2.44] | 24.0 [52.9] |

| For very hard materials - with universal hoisting eye | |||||||||||||

| EVU-0.5H | 0,5 | 0-16 [0-0.63] | 39 [1.54] | 226 [8.91] | 134 [5.29] | 40 [1.59] | 41 [1.63] | 22 [0.88] | 114 [4.49] | 13 [0.53] | 20 [0.80] | 28 [1.12] | 1.9 [4.19] |

| EVU-1H | 1 | 0-20 [0-0.75] | 39 [1.54] | 237 [9.35] | 145 [5.73] | 52 [2.06] | 44 [1.74] | 28 [1.12] | 127 [5.00] | 13 [0.53] | 20 [0.80] | 28 [1.12] | 2.1 [5.29] |

| EVU-2H | 2 | 0-35 [0-1.38] | 68 [2.68] | 375 [14.78] | 209 [8.24] | 76 [2.99] | 61 [2.43] | 48 [1.90] | 192 [7.58] | 18 [0.71] | 32 [1.27] | 44 [1.74] | 7.6 [18.3] |

| EVU-3H | 3 | 0-40 [0-1.56] | 73 [2.89] | 446 [17.56] | 262 [10.34] | 101 [4.01] | 71 [2.80] | 52 [2.17] | 299 [9.30] | 22 [0.90] | 42 [1.65] | 58 [2.29] | 14.8 [32.6] |

| EVU-5H | 5 | 0-40 [0-1.56] | 73 [2.89] | 446 [17.56] | 262 [10.34] | 101 [4.01] | 71 [2.80] | 52 [2.17] | 299 [9.30] | 22 [0.90] | 42 [1.65] | 62 [2.44] | 16.0 [35.3] |

| EVU-6H | 6 | 0-50 [0-2.00] | 80 [3.15] | 549 [21.64] | 327 [12.89] | 131 [5.19] | 97 [3.84] | 59 [2.32] | 284 [11.18] | 37 [1.46] | 42 [1.65] | 62 [2.44] | 24.0 [52.9] |

| For stainless steel - with universal hoisting eye | |||||||||||||

| EVU-0.5S | 0,5 | 0-16 [0-0.63] | 39 [1.54] | 226 [8.91] | 134 [5.29] | 40 [1.59] | 41 [1.63] | 22 [0.88] | 114 [4.49] | 13 [0.53] | 20 [0.80] | 28 [1.12] | 1.9 [4.19] |

| EVU-1S | 1 | 0-20 [0-0.75] | 39 [1.54] | 237 [9.35] | 145 [5.73] | 52 [2.06] | 44 [1.74] | 28 [1.12] | 127 [5.00] | 13 [0.53] | 20 [0.80] | 28 [1.12] | 2.1 [5.29] |

| EVU-2S | 2 | 0-35 [0-1.38] | 68 [2.68] | 375 [14.78] | 209 [8.24] | 76 [2.99] | 61 [2.43] | 48 [1.90] | 192 [7.58] | 18 [0.71] | 32 [1.27] | 44 [1.74] | 7.6 [18.3] |

| EVU-3S | 3 | 0-40 [0-1.56] | 73 [2.89] | 446 [17.56] | 262 [10.34] | 101 [4.01] | 71 [2.80] | 52 [2.17] | 299 [9.30] | 22 [0.90] | 42 [1.65] | 58 [2.29] | 14.8 [32.6] |

| EVU-5S | 5 | 0-40 [0-1.56] | 73 [2.89] | 446 [17.56] | 262 [10.34] | 101 [4.01] | 71 [2.80] | 52 [2.17] | 299 [9.30] | 22 [0.90] | 42 [1.65] | 62 [2.44] | 16.0 [35.3] |

| EVU-6S | 6 | 0-50 [0-2.00] | 80 [3.15] | 549 [21.64] | 327 [12.89] | 131 [5.19] | 97 [3.84] | 59 [2.32] | 284 [11.18] | 37 [1.46] | 42 [1.65] | 62 [2.44] | 24.0 [52.9] |